CAPPING

03 03

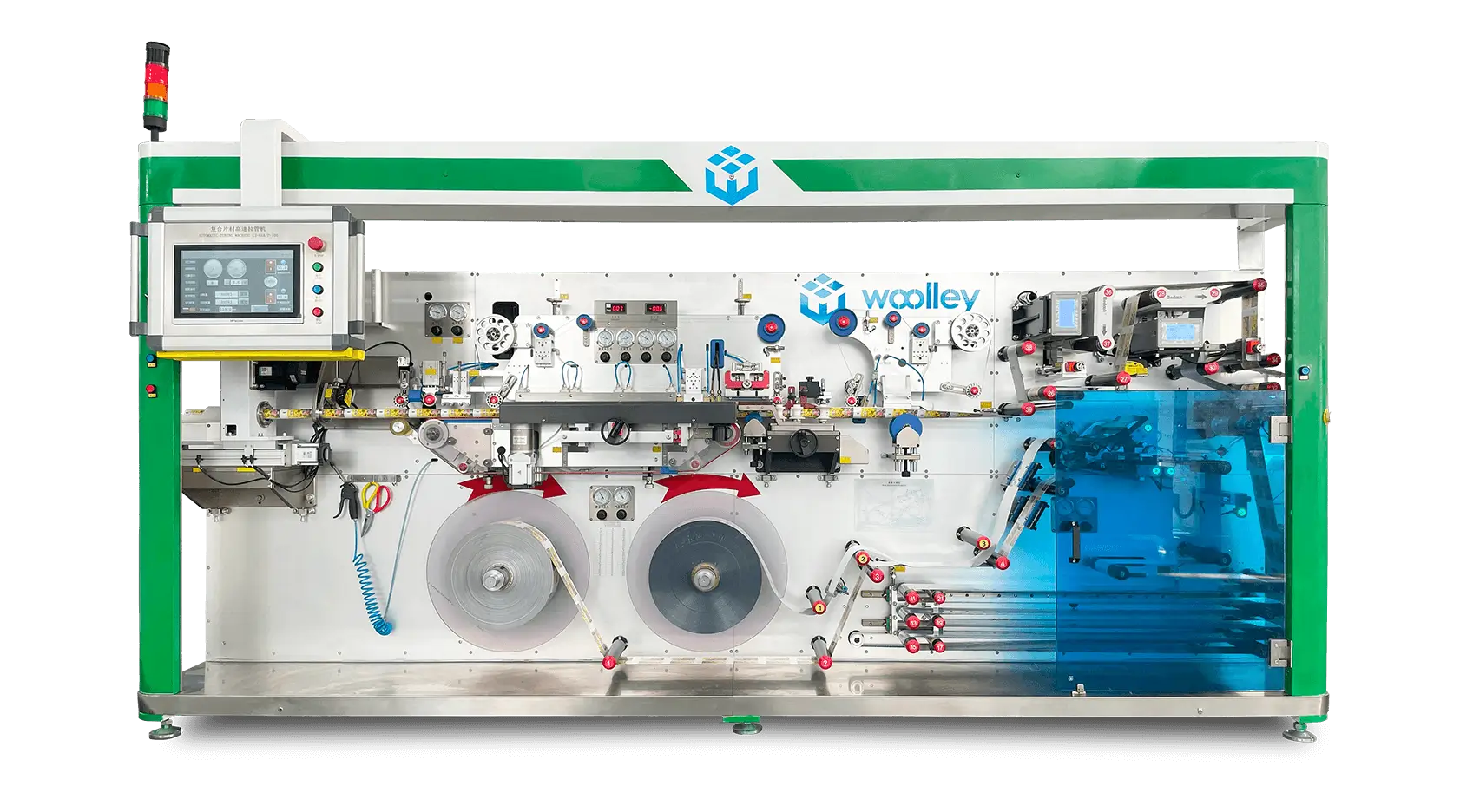

Full-automation equipment is used for a one-stop completion of making orifice, foil seal and capping; together with the detection of the product surface and the missing film, a stable quality is ensured.

Apply the full-automation production process; the printed film is welded into the round tube; multi-layer laminated composite structure containing an EVOH barrier layer with high barrier property.Unlike PE tube, film laminated tube has glossy texture and the firmness and elasticity of Aluminum.

WOOLLEY independently develops automatic heading technology, Ensure the appearance of the tube head is stable.

Before

Before

After

After

Full-automation equipment is used for a one-stop completion of making orifice, foil seal and capping; together with the detection of the product surface and the missing film, a stable quality is ensured.

The advanced internal heating sealing machine is used to provide vertical, horizontal or rhombic sealing stripes, enhancing the overall beauty of the product.

WhatsApp us

Adding {{itemName}} to cart

Added {{itemName}} to cart