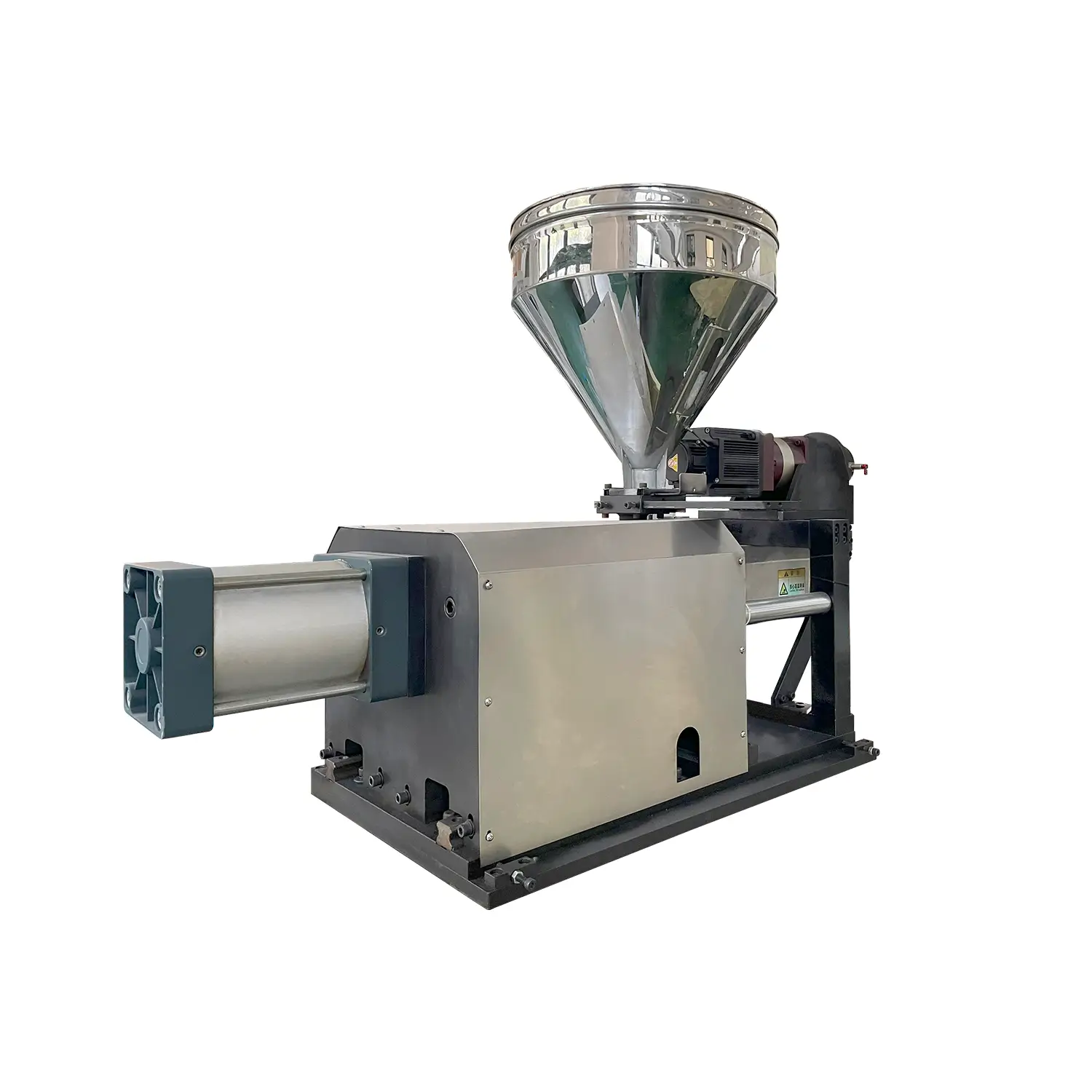

JX-HS60

Tube Heading Machine JX-HS60

Tube Heading Machine JX-HS60 Patent of innovation,heading by vertical-upward compression-molding technology is adopted. The machine is driven and controlled by the most advanced Servo Mechanism, especially for the quantitative dripping/spraying and high-pressure compressing/shaping process. No hydraulic technology is adopted during the whole running.

woolley Tube Machine

Features

Fast and high precision

Servo automation control

Stable and easy to operate

Suitable for a variety of materials

Quick conversion specifications

woolley Tube Machine

Application

Beauty Care Package

Health Care Package

Food Care Package

Home Care Package

Personal Care Package

woolley Tube Machine

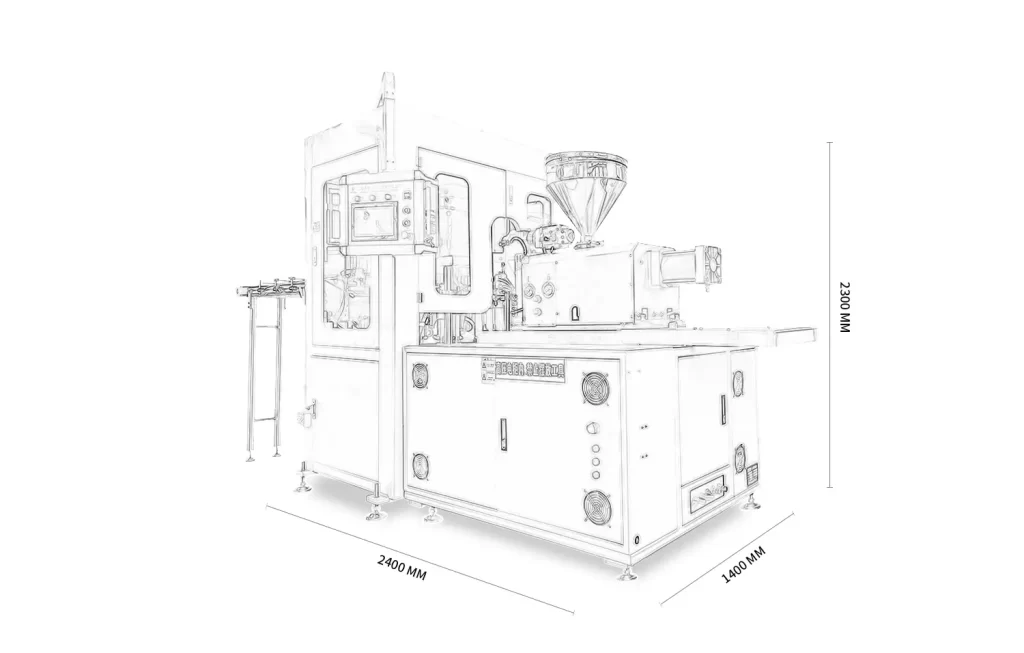

Parameters

Real Customer • Stories

Hear from them

SMC

We are a cosmetic tube manufacturer,before we order this machine,we visited woolley factory.They received us warmly and demonstrated the printing machine to us on the spot. Now their engineers are installing the machines in our factory.

ALBEA

We received the machine 10days before,looking forward to the machine being put into production as soon as possible.

SCHNEIDER

We produce toothpaste ourselves,we bought tubes from local market before.Now we can produce the tubes ourselves,and we also can supplier tubes to other customers.

FESTO

Received it,now they help us to install it and adjust it.Can’t wait to see it running.

DANFOSS

We bought 6 color offset printing machine,it’s good printing for complex patterns,like human face and fruits,ect.Good machine!

BEAUTY STAR

High quality laminated tube machine,ABL and PBL are running well.

KESIYU

We bought this JX-120 high speed shoulder machine.Very good quality,and now it running well in my factory.

GZ SANRONG

A pesar del parón navideño por el que la entrega se ha retrasado unos días, hemos recibido nuestra máquina de letterpress correctamente. Fuimos atendidos por chen, que tuvo la amabilidad y profesionalidad de guiarnos en el proceso en todo momento.

All comments are excerpted from WOOLLEY official promotional media . Such as alibaba

FAQ

WOOLLEY has compiled the frequently encountered problems during the entire purchasing process for your reference.

Yes, We are the manufacturer and trading company.

The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc

All our machine have one year guarantee, starting from finished installation.