CAPPING

04 04

Full-automation equipment is used for a one-stop completion of making orifice, foil seal and capping; together with the detection of the product surface and the missing film, a stable quality is ensured.

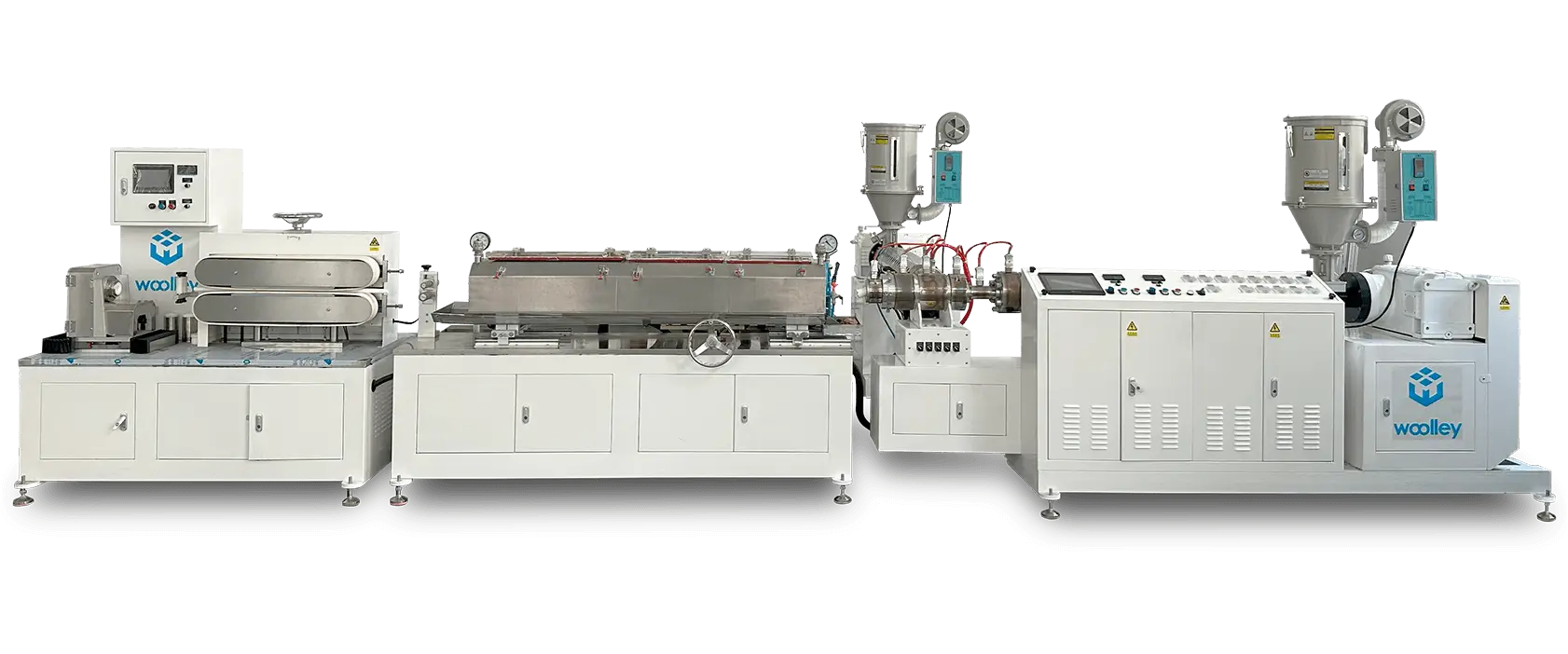

Extrusion Tube Production Lines 360°seamless design; process: multi-layer co-extruding and heating; five types: 1-layer, 2-layer, 3-layer , 5-layer and 6-layer

Extrusion tube production lines-heading Machine accomplishes tube end forming ,high precision, easy to operate

Before

Before

After

After

Four major printing processes, silkscreen print, offset print, flexo print and hot stamping, are used to provide various visual and tactile presentations.

Full-automation equipment is used for a one-stop completion of making orifice, foil seal and capping; together with the detection of the product surface and the missing film, a stable quality is ensured.

The advanced internal heating sealing machine is used to provide vertical, horizontal or rhombic sealing stripes, enhancing the overall beauty of the product.

WhatsApp us

Adding {{itemName}} to cart

Added {{itemName}} to cart