A. Two kind tube heading making machine, heading injection machine and heading compress machine,What is the difference between the two?

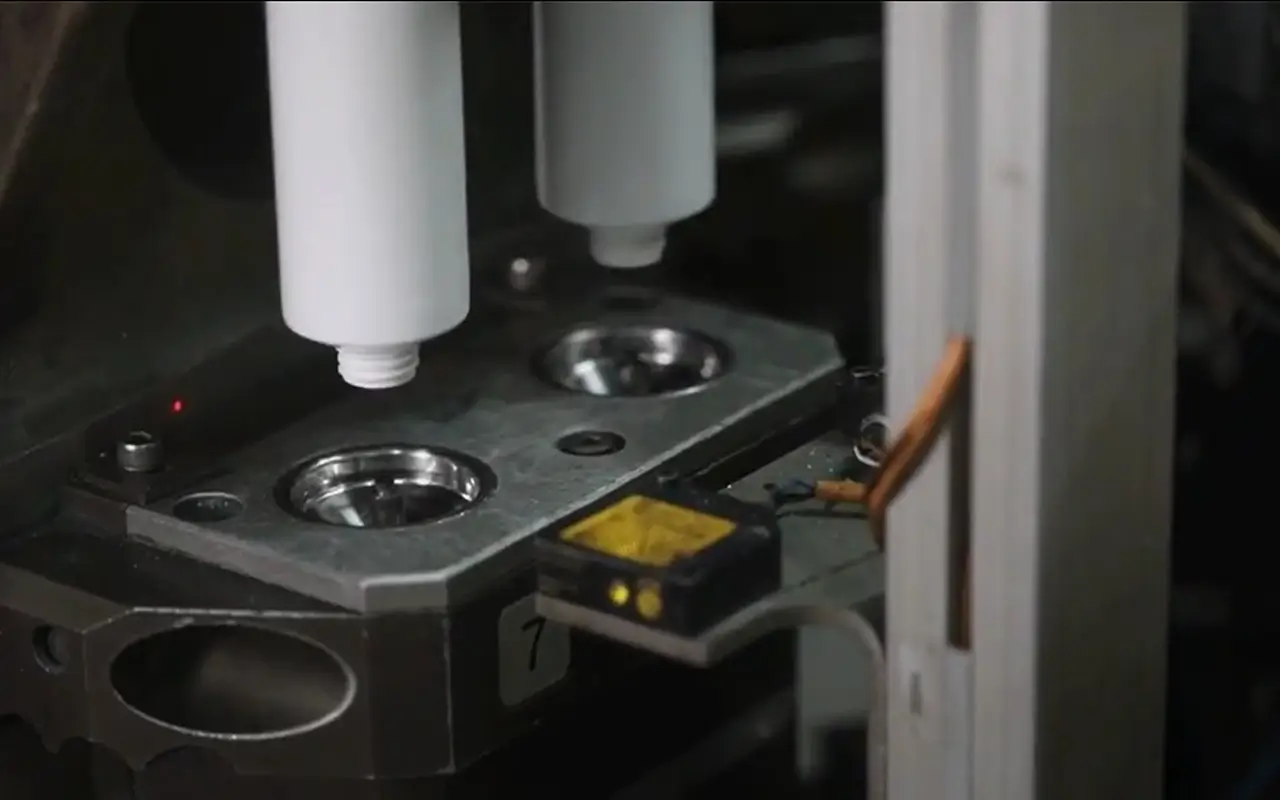

Please check the video attached, “tube heading injection machine“, “tube heading compress machine”. Although both belong to tube heading making machine, there are many differences in the tube manufacturing process.

B. How the heading formed?

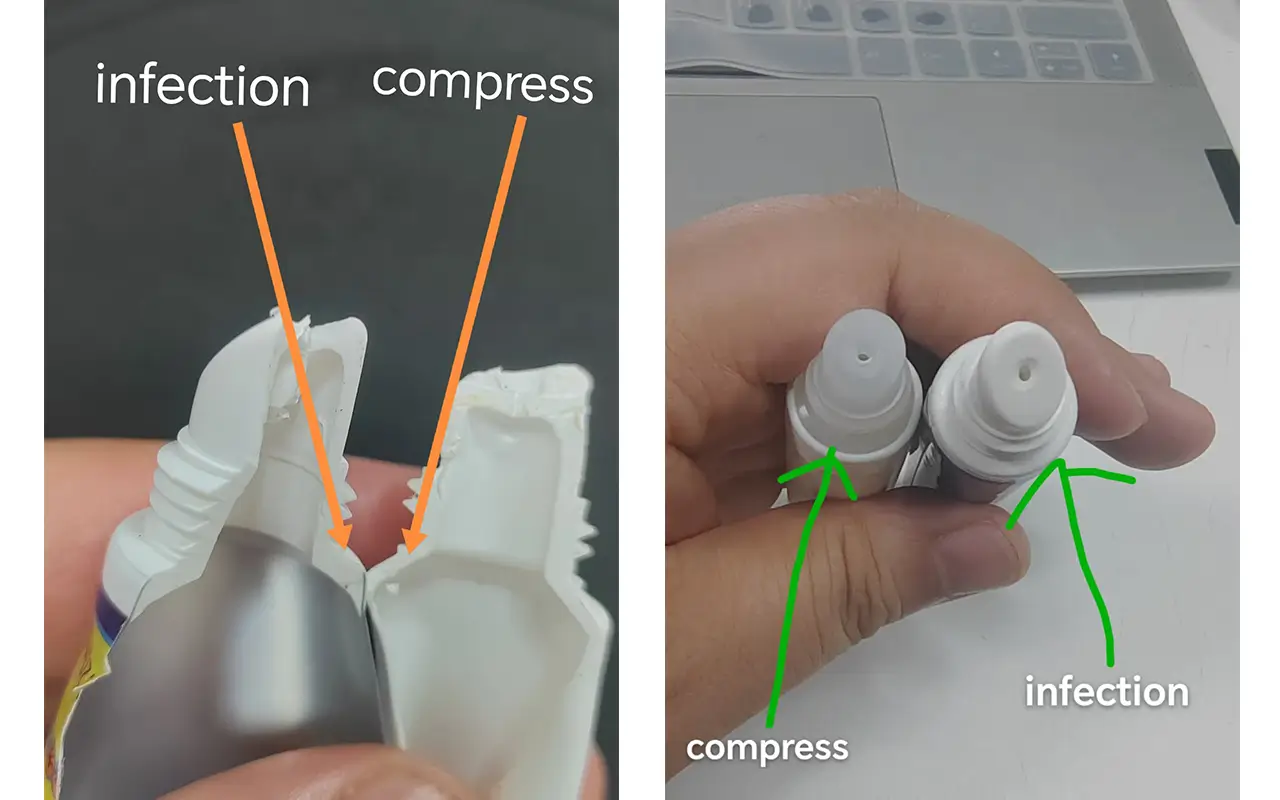

Tube heading injection machine need hot runner injection mold, it has a material spray point, after material sprayed into mold, tube head formed, it need use a machine to make orifice(hole) on the head part(please check the picture below)

Tube heading compress machine is different, it spray material on mandrel, and then the mold compress(closed),after the tube head formed, the mold open, it can form heading and orifice(hole) together, not need another process to make orifice on tube head(please check the picture below).

C. Orifice appearance

The orifice appearance of Tube heading compress machine is better than tube heading injection machine. (Please check the picture below)

D. Shoulder thickness

Injection mold need to make shoulder thicker, compress mold can make shoulder part thinner. Same diameter tubes, thinner shoulder can save more material.

E. Probability error of heading forming

Tube heading injection machine has 16 pieces tube heading units on it’s forming part, the probability of problems with head molding will be higher than compress tube heading machine(only have 2 pieces tube heading units)

F. Mold changing time

Tube heading injection machine has a long mold changing time, it will take about one day to change mold. Tube heading compress machine very short mold changing time, usually 30minutes to 60minutes.If you change tube size one time every month, we suggest you tube heading injection machine. If you need to change tube size very day, tube heading compress machine is the best.

For more information about tube heading making machine, please contact Woolley