How to conduct to research and evaluate the prospects and returns of investing for 2 lines of automated cosmetic soft tube packaging manufacturing equipment line from China Woolley?

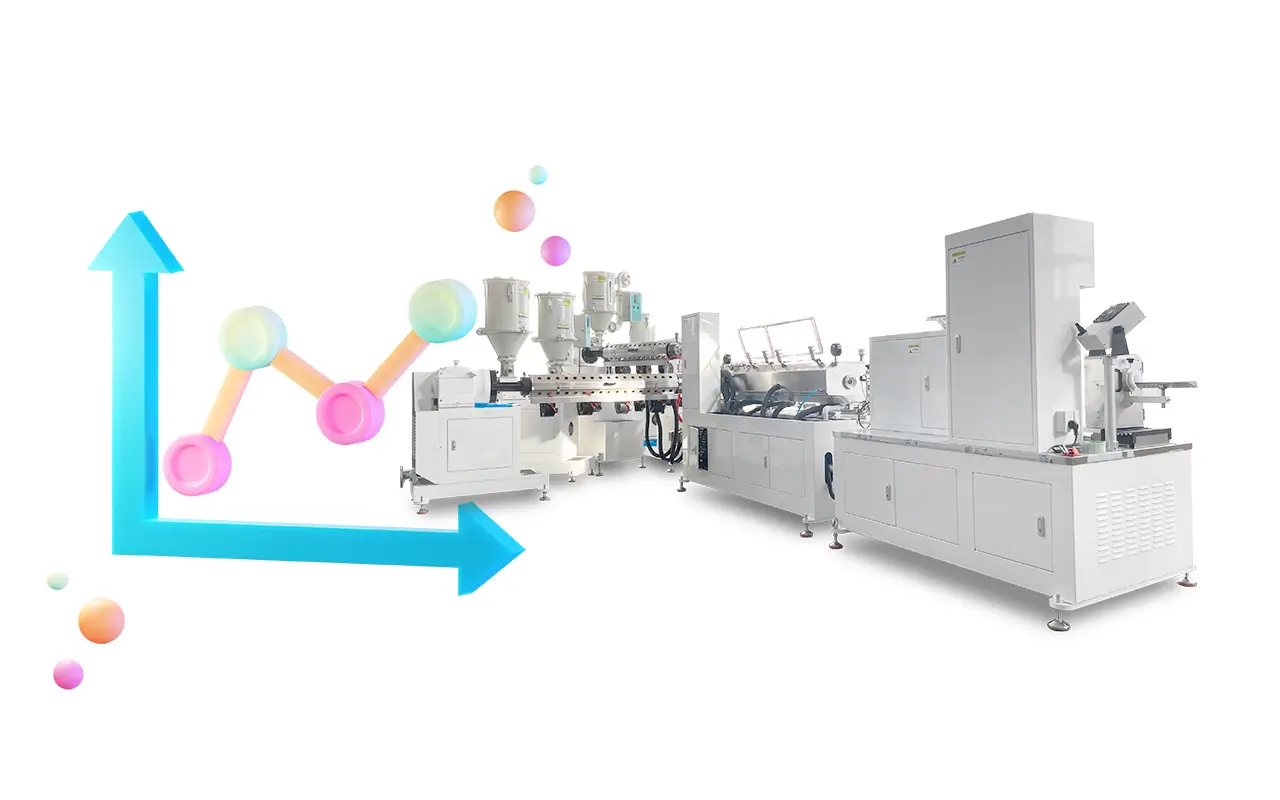

“Cosmetic soft tube packaging manufacturing equipment line ”

All right, in the manufacturing and processing industry in local country, when the management plan to determine a comprehensive and comprehensive feasibility investment report, the company’s business development director will start this work.

Woolley line includes the PE extruding line and laminated tube line.

When conducting the investment and return analysis of the fully automated cosmetic soft tube packaging manufacturing equipment, multiple aspects need to be considered, including initial investment cost, operating cost, benefit improvement, return on investment (ROI) analysis and risk factors. The following are specific analysis steps:

Initial investment cost

Equipment purchase: including the purchase cost of fully automated equipment.

Installation and commissioning: the cost of equipment installation and commissioning.

Employee training: training employees who operate and maintain equipment.

Initial maintenance: basic maintenance costs to ensure the smooth operation of equipment.

Operation cost

Power consumption: electricity required for the operation of fully automated equipment.

Maintenance and maintenance costs: the cost of regular maintenance of equipment.

Equipment depreciation: the part of the equipment that depreciates over time.

Labor cost: wages of employees who operate and maintain equipment.

Efficiency improvement

Production efficiency improvement: automated production lines can achieve 24-hour uninterrupted production.

Product quality stability: reduce human errors and ensure the consistency and professionalism of product packaging.

Improved market competitiveness: Fast and flexible production capacity helps companies better respond to market demand.

Return on investment (ROI) analysis

Calculation formula: ROI = net profit / investment cost × 100%.

Payback period: The payback period of fully automatic packaging lines is usually between 1 and 3 years.

Return on investment (ROI) analysis

Calculation formula: ROI = net profit / investment cost × 100%.

Payback period: The payback period of fully automatic packaging lines is usually between 1 and 3 years.

Risk factors

Technological upgrading: Rapid technological development may cause existing equipment to become obsolete.

Equipment maintenance and repair: High professionalism may affect the normal operation of the production line.

Risk factors

Technological upgrading: Rapid technological development may cause existing equipment to become obsolete.

Equipment maintenance and repair: High professionalism may affect the normal operation of the production line.

Market demand analysis

Market size: The market size of China’s tube filling and packaging production line industry continues to expand, and it is expected that by 2025, the market size is expected to exceed 200 billion yuan.

Growth trend: The industry has shown a steady growth trend, with a compound annual growth rate of 15%.

Technology development trend

Automation and intelligence: The demand for high-end intelligent tube filling and packaging production lines is growing rapidly.

Environmental protection technology: The sales of environmentally friendly tube packaging production lines increased by nearly 30%, showing that the industry’s acceptance and application of environmental protection technology has deepened.

By comprehensively considering the above factors, companies can conduct a comprehensive return on investment analysis and make more informed investment decisions.

Get a deep detail of line investment feasibility report from Woolley sales consultants is then on your table, www.wo-olley.com