Choosing the right Ink for tube offset printing machines is crucial for achieving high-quality prints and maximizing production efficiency. Here’s a comprehensive guide to help you make informed decisions, ensuring your printed tubes meet both aesthetic and functional standards.

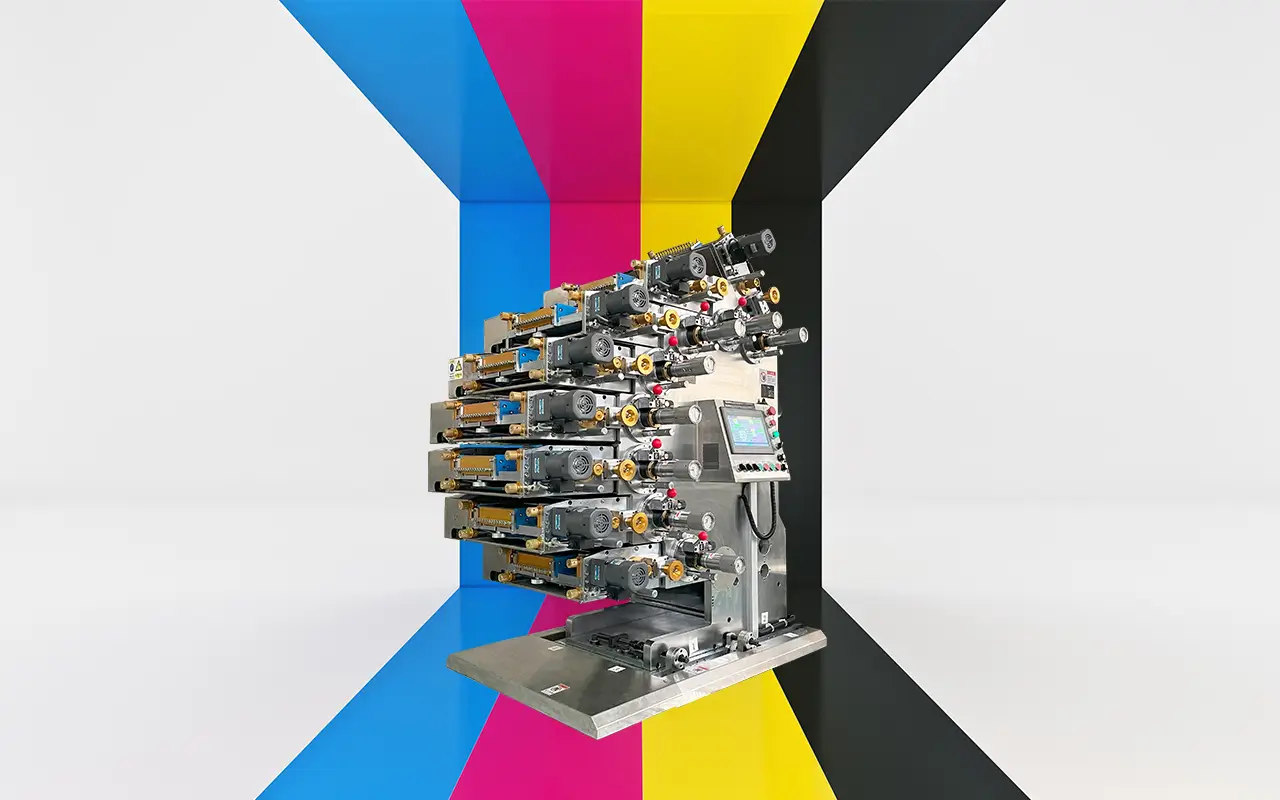

“Exploring the Versatility of Offset Printing Machines”

1. Understand Ink Types

Water-Based Inks: Ideal for eco-friendly printing, these inks are perfect for non-porous surfaces and provide good adhesion. They are less toxic and easier to clean.

Solvent-Based Inks: Known for their strong adhesion and durability, these inks are suitable for plastic tubes, making them a popular choice for various applications.

UV Inks: These inks cure instantly under UV light, offering vibrant colors and excellent resistance to scratching and fading, which is essential for high-quality finishes.

2. Consider Substrate Compatibility

Different tube materials (like polyethylene, polypropylene, or PVC) require specific ink formulations. Always verify that the ink you choose is compatible with the substrate to ensure optimal adhesion and print quality.

3. Evaluate Print Quality

Look for inks that provide vibrant colors, excellent consistency, and durability. Conduct test prints to assess how well the ink performs on your specific tube materials and ensure it meets your visual standards.4. Assess Drying Speed

The drying time of the ink is critical in a fast-paced production environment. Choose inks that dry quickly, such as UV inks, to keep your production line moving and reduce turnaround times.

5. Review Color Range

Select inks that offer a broad spectrum of colors. Many manufacturers provide custom color matching services, allowing you to achieve the exact shades required for your branding.

6. Check Adhesion Properties

Ensure that the ink adheres well to the tube surface, especially for products exposed to moisture or handling. This prevents smudging and ensures longevity.

7. Be Mindful of Environmental Regulations

Consider the environmental impact of the inks you choose. Low-VOC (volatile organic compounds) inks are often required to comply with regulations, making them a safer option for both workers and the environment.8. Choose a Reliable Supplier

Opt for reputable ink suppliers who offer technical support and guidance. A good supplier can provide samples for testing, helping you determine the best ink for your needs.9. Factor in Cost

While price is important, consider the overall value the ink provides. Higher-quality inks may cost more upfront but can lead to reduced production costs and improved product quality in the long run.10. Conduct Thorough Testing

Before committing to a specific ink, perform print tests to see how it interacts with your printing process and tube materials. This step is essential to avoid potential issues in production.

Conclusion

Choosing the right ink for tube offset printing machines is vital for achieving high-quality results. By understanding the different types of inks, their compatibility with substrates, and their performance characteristics, you can make informed choices that enhance your printing processes. Follow these guidelines to ensure your printed tubes not only look great but also meet your production and environmental standards.