Many of our customers, especially those who just entered the cosmetics tube industry, do not know much about 1/2/3/5/6 layer tube extruders, and often asked is what is the difference between the extruder, one layer, two layer, three layers, five layers and six/seven layers.

“1/2/3/5/6 layer tube extruders”

Here to give you a brief introduction:

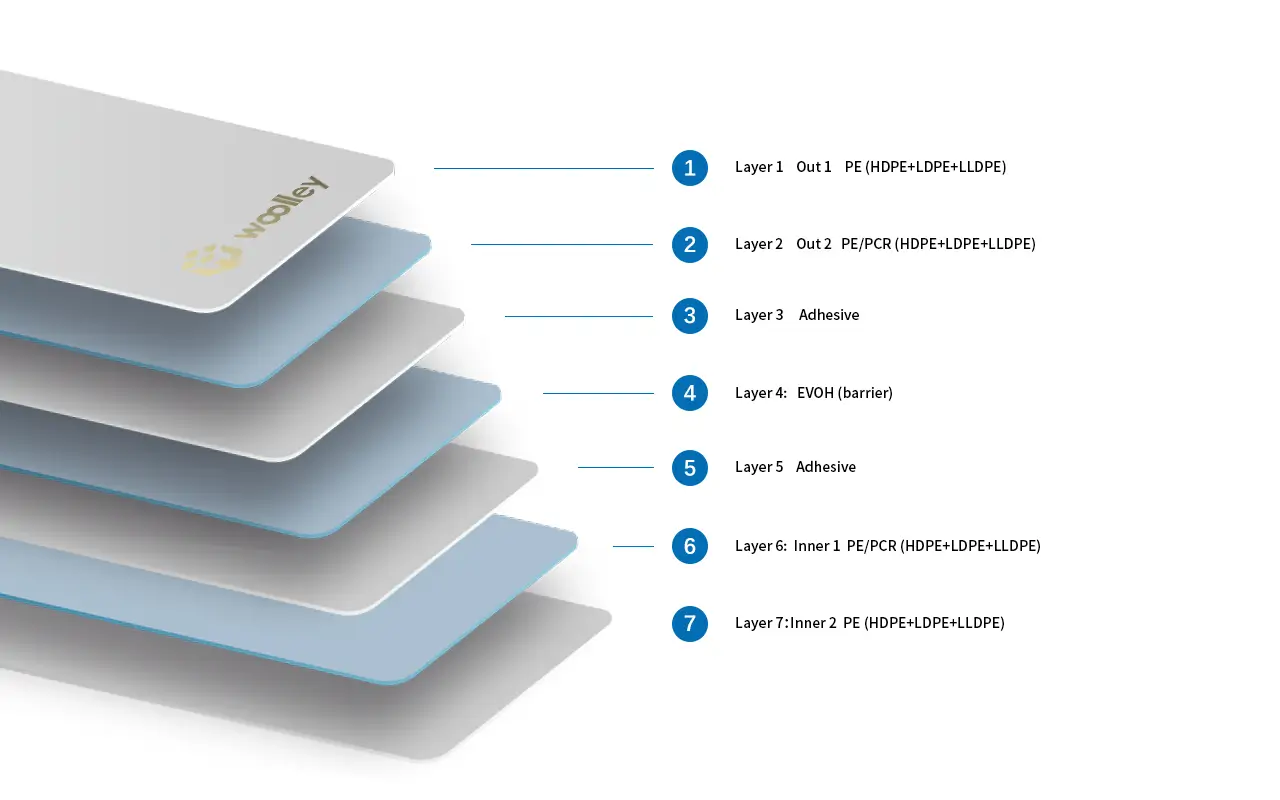

- The tubes aredivided into single layer, double layer, five layers etc.. Double layer tube is more commonly used, If it is a low and medium grade can also be used single layer. Five layers of tube is including the outer layer, the inner layer, two bonding layers, and another barrier layer. It has excellent gas barrier performance, which can effectively prevent the infiltration of oxygen and odor gases, and prevent the seepage of content fragrance and effective ingredients. The barrier layer can be a multi-layer composite material of EVOH, PVDC, oxide coating, etc.

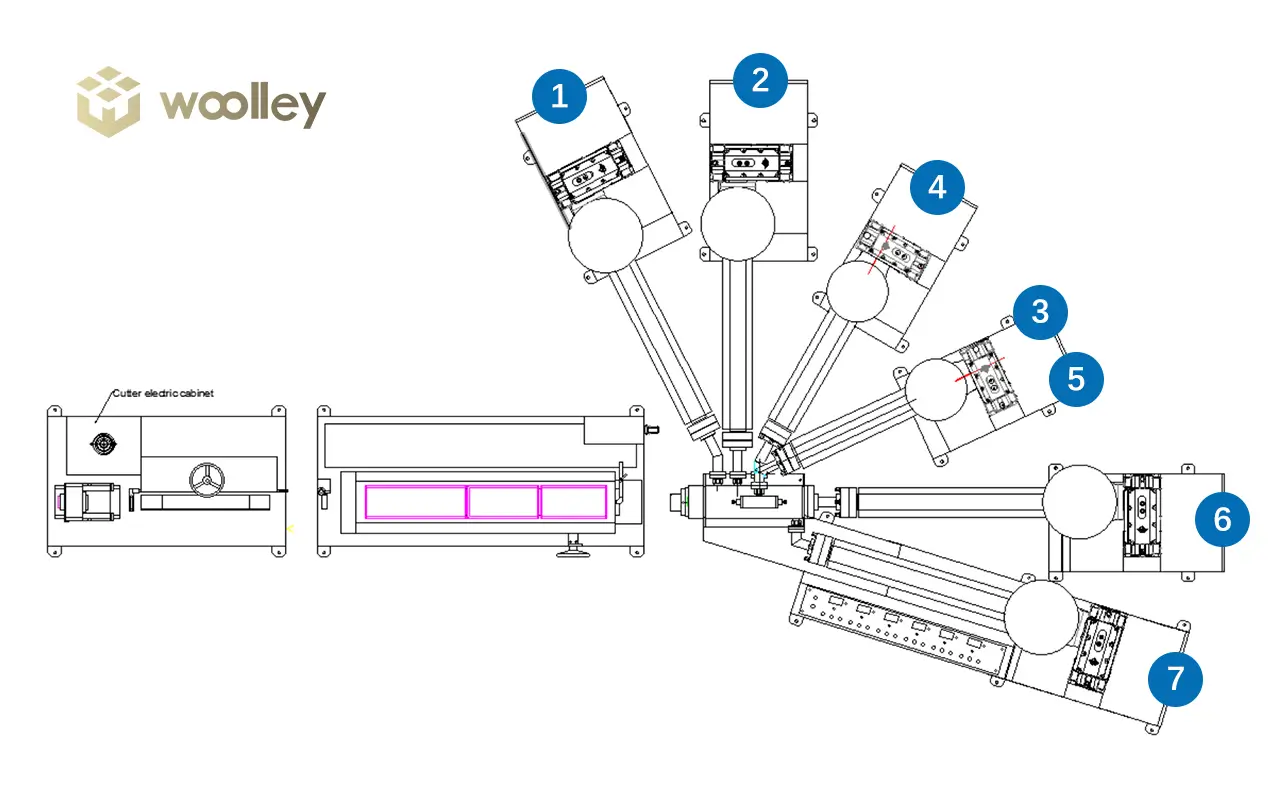

- Of course, Producingseveral layers of PE tube needs several layers of extruder. The precision of the extruder, whether the mold is high quality, the configuration will directly affect the quality of the extruded tube, such as whether the wall thickness is consistent, there is no leakage of glue, whether the tube cutting is good, whether the appearance of the tube color is uniform, no obvious color difference, the surface should be smooth, no burr and scratches, There are no cracks or bubbles.

Therefore, if you plan to buy the 1/2/3/5/6 layer tube extruders to produce cosmetics tubes, please first think about the production of several layers of tube, it needs the corresponding extruder, but also related to your production cost, the price of different layers of extruder is very different.